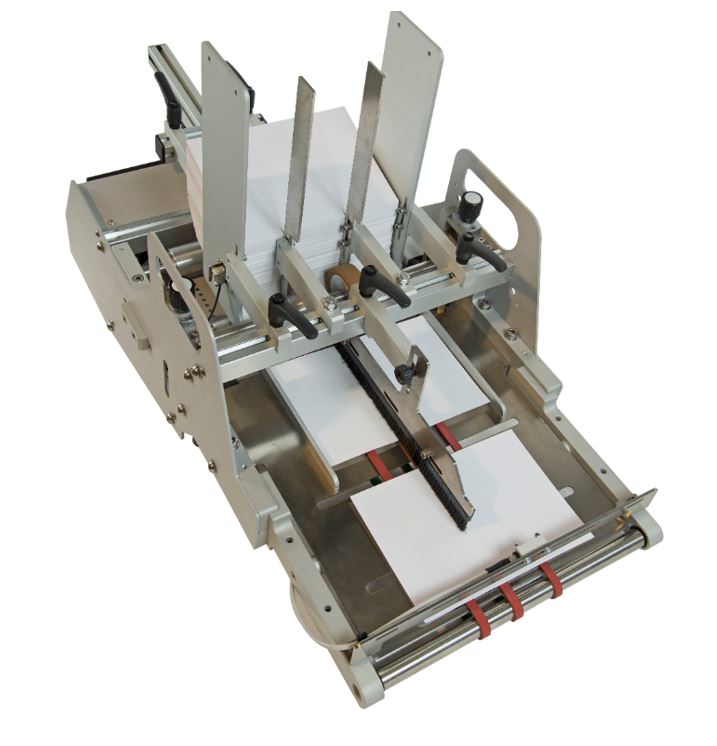

Feeder

The feed selection uses rubber counterrotating rollers with micro adjustments on both the left and right side, which make the feeder extremely flexible for any type of product. The 300 mm high loading unit, equipped with minimum load capacity control, guarantees a great working autonomy.

WR FEEDER is controlled by a microprocessor which uses an LCD display keypad with two 20-character rows and 7 function keys to interface with the user. Through this, it is possible to set all the working parameters, such as continuous feed or multiple copies on demand, feeding speed, stop delay, print delay and stroke counter.

| Product min width | 60 x 60 mm |

| Product max width | 500 x 300 mm |

| Product thickness | from 0,20 mm up to 10,00 mm |

| Feeding speed | from 40 up to 60 m/min. |

* Available in two versions:

- Standard output terminal

- Oversized output terminal suitable for the integration of marking or labeling systems

| Data Sheet | SCARICA IL PDF |

|---|---|

Larghezza passaggio carta |

30 mm min. – 200 mm max |

Lunghezza etichetta |

30 mm min. – 330 mm max |

Portabobina |

Ø esterno 250 mm max

Ø anima 40 mm

Ø 45–76 mm con adattatori

|

Lettura interspazio etichette |

con fotocellula a forcella |

Regolazione pre erogazione |

elettronica ad impostazione digitale |

Velocità avanzamento etichetta |

etichetta:~ 12 m/min. (valore |

Velocità rotazione prodotto |

~ 12 m/min. (valore fisso) |

Selezione 1-2 etichette |

elettronica ad impostazione digitale

|

Alimentazione elettrica |

220-230 V, 50-60 Hz, 200 W

|

Dimensioni |

750 x 450 x 450 mm |

Peso |

26 Kg. (bobina etichette esclusa) |

Label Engineering reserves the right to make construction changes without prior notice that may lead to changes in the characteristics or performances indicated.