Apply Label PN

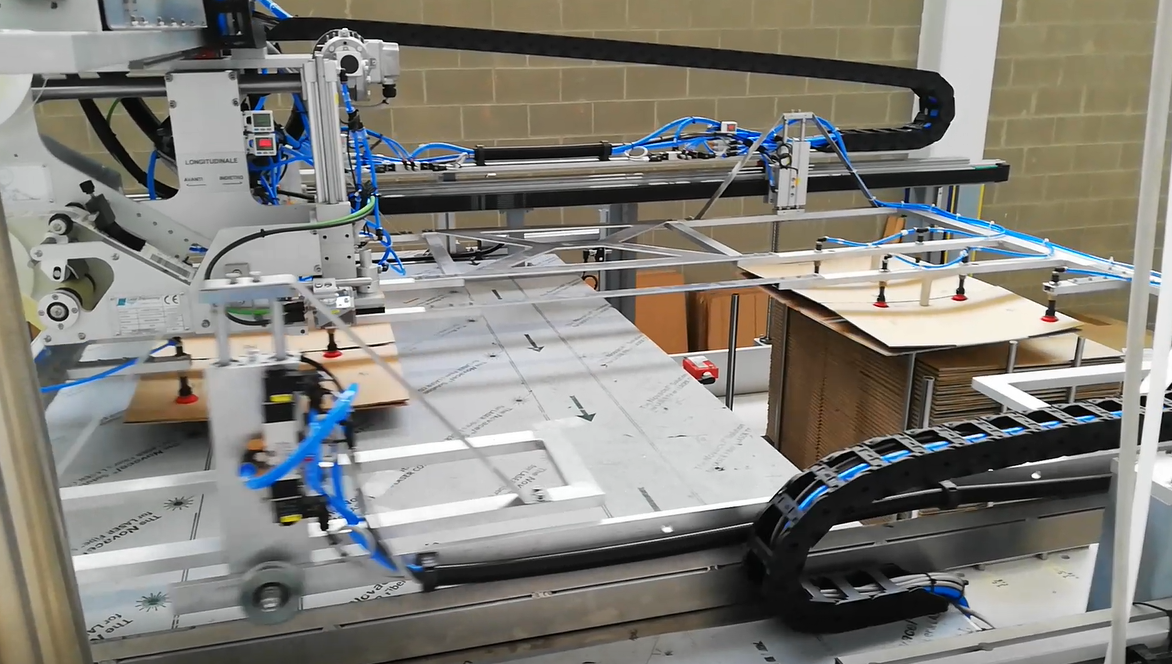

The packaging line provides an accumulation system for the flat boxes, placed in the correct position to be “sucked" by the Pick & Place device.

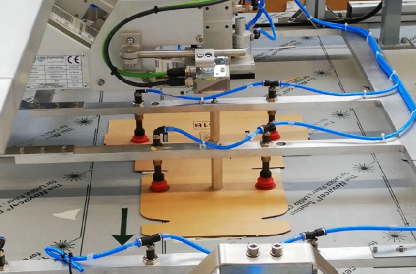

Thanks to the handling unit, the cardboard box is put under the labelling station for the application of a pre-printed label with barcode.

The labelling system is equipped with a device for detecting the label presence and sequential verification of the barcode.

At the end of the control phase, a second Pick & Place group recovers the labelled boxes to place them in the unstacker device for easy recover by the operator.

Labelling unit with double product handling system.

| Label size | 100 x 100 mm |

| Storage capacity | 150 boxes |

| Multi-format boxes | from 200 x 300 up to 600 x 800 |

| Data sheet | SCARICA IL PDF |

|---|---|

Larghezza passaggio carta |

30 mm min. – 200 mm max |

Lunghezza etichetta |

30 mm min. – 330 mm max |

Portabobina |

Ø esterno 250 mm max

Ø anima 40 mm

Ø 45–76 mm con adattatori

|

Lettura interspazio etichette |

con fotocellula a forcella |

Regolazione pre erogazione |

elettronica ad impostazione digitale |

Velocità avanzamento etichetta |

etichetta:~ 12 m/min. (valore |

Velocità rotazione prodotto |

~ 12 m/min. (valore fisso) |

Selezione 1-2 etichette |

elettronica ad impostazione digitale

|

Alimentazione elettrica |

220-230 V, 50-60 Hz, 200 W

|

Dimensioni |

750 x 450 x 450 mm |

Peso |

26 Kg. (bobina etichette esclusa) |

Label Engineering reserves the right to make construction changes without prior notice that may lead to changes in the characteristics or performances indicated.